Define Requirements

Collect and define client requirements including product specifications, materials, design style, and quality standards. Ensure a clear direction for development and production.

View Details

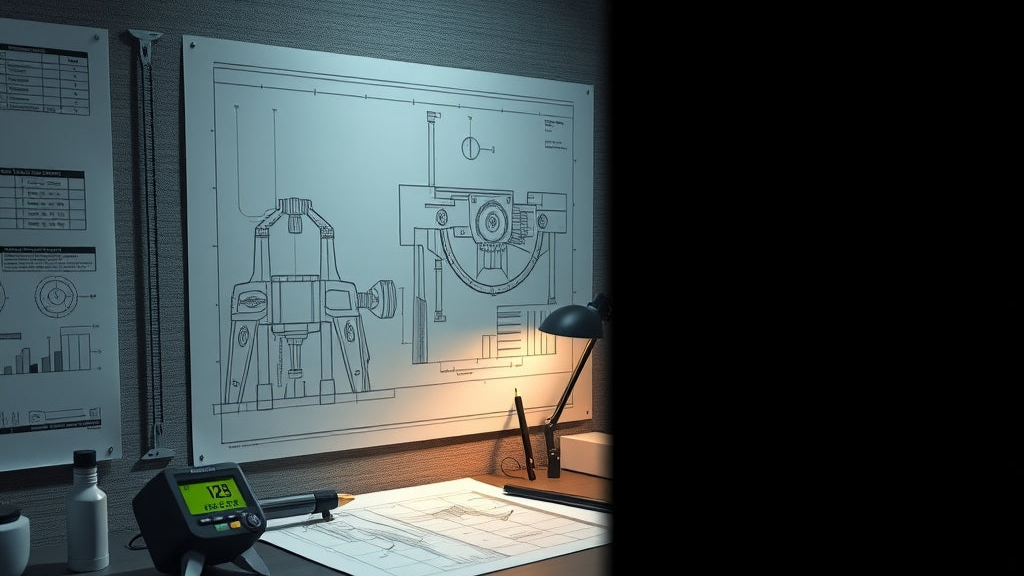

Design & Engineering

Complete detailed product design, including 3D modeling, CAD drawings, and production feasibility. Optimize structure and manufacturing process.

View Details

Prototype & Approval

Produce prototypes or functional samples for testing and validation. Collect client feedback and obtain approval before mass production.

View Details

Tooling & Prep

Create production tooling, jigs, and fixtures. Prepare raw materials and production line to ensure smooth mass production.

View Details

Mass Production

Launch full-scale production after sample approval. Strictly control quality, production schedule, and consistency.

View Details

Delivery & Support

Deliver products according to contract. Provide technical support, warranty services, and collect client feedback for continuous improvement.

View DetailsOur Services – Steel Furniture OEM & ODM

We provide comprehensive OEM & ODM solutions in steel furniture, serving diverse applications including homes, offices, education, healthcare, warehouses, and more.

Customized Steel Furniture Solutions for Every Project – Since 1994

Why Choose Us

- With over 31 years of experience in steel furniture manufacturing, we deliver precision, reliability, and innovation across every project.

- From customized design and prototyping to batch production and delivery, our comprehensive ODM & OEM services ensure high-quality solutions tailored to your office, home, or commercial needs.

- Partner with us to transform your ideas into reality efficiently and professionally.

Years of Experience

Global Clients

Factory Area

International Certifications

Rapid Prototyping

Why We Stand Out

- We combine decades of expertise with advanced manufacturing processes to deliver steel furniture solutions that make a real difference.

- Our team ensures every project is handled with precision, flexibility, and attention to detail, providing clients with reliable and innovative products they can trust.

- With a commitment to quality and customer satisfaction, we strive to exceed expectations on every project, setting us apart in the industry.

Step 1

Define Requirements

Engage in in-depth discussions with the client to clarify product specifications, functions, materials, dimensions, budget, and delivery schedule.

Collect user requirements, market research data, and competitive analysis to ensure clear project objectives, laying a solid foundation for subsequent design and production.

Step 2

Design & Engineering

Based on confirmed requirements, create product designs and engineering plans, including 3D drawings, structural design, and functional validation.

Evaluate material selection, manufacturing feasibility, and cost control to ensure the design is both practical and visually appealing.

Step 3

Prototype & Approval

Produce samples or small trial batches for client review to verify functionality, appearance, and craftsmanship.

Gather client feedback and make refinements to ensure the product meets quality standards and expectations.

Step 4

Tooling & Prep

Prepare production tools and molds according to the finalized prototype, and ready all equipment and raw materials.

Ensure that resources and processes are fully prepared for smooth large-scale production.

Step 5

Mass Production

Carry out large-scale production following the approved prototype, strictly adhering to quality control procedures.

Through standardized operations and regular inspections, guarantee product consistency, safety, and reliability.

Step 6

Delivery & Support

Complete logistics and delivery, provide installation guidance, operation manuals, and technical support.

Ensure smooth product use, offer after-sales service, and provide continuous improvement recommendations to enhance client satisfaction and trust.

Partner With byshtec

From advanced manufacturing to trusted global delivery,

every step we take is to empower your business.

Share your needs below — let’s shape the future together.